2021-07-15

"New opportunities through technological change"

The German RINGSPANN Group is pushing ahead with the internationalisation of its supply business

A few days ago, RINGSPANN broke ground on another production hall with an office wing at its headquarters in Bad Homburg. Once again, the corporate group is strengthening its position as an international one-stop supplier for clutches, couplings and brakes as systematic components of power transmission. For Managing Director Fabian Maurer, however, this new building is just one of a number of measures designed to help achieve ambitious growth targets, especially for the freewheels, brakes, shaft-hub connections and shaft couplings product divisions. In this interview, the company boss discusses which core competencies and business areas the company will be focusing on in order to be even more agile in key industries and future markets.

Mr. Maurer, are you satisfied with the current development of the company?

Maurer: Generally speaking, yes. After a brief, Corona-related slump, RINGSPANN is back on a growth path that gives us confidence. We are continuing on our path to becoming an international full-range supplier of high-quality clutches, couplings and brakes and are aiming to significantly increase our turnover. To this end, we have recently implemented many important measures, from which point we are now tackling the next strategic goals.

Which areas are you placing the key emphasis on here?

Maurer: In addition to continuous process optimisation and employee qualification, we are intensely devoted to further developing our product and service range, improving our customer focus and sales activities, as well as the further digitalisation of the company. All activities in these areas are closely linked and serve the overriding goal of the ongoing internationalisation of the RINGSPANN Group.

Taking the product portfolio as a starting point, can you outline how you go about this?

Maurer: Within our product portfolio we have now defined freewheels, brakes, shaft-hub-connections and shaft couplings as special areas of focus. For various reasons, these are the areas in which we see considerable growth potential. The global markets for these products are large and RINGSPANN, as a global quality supplier with increasingly international value creation and its own development and engineering know-how, is perfectly poised to excel. We are therefore an attractive partner both for the realisation of complex large-scale projects and to supply customers in new or emerging markets with a highly innovative dynamic - such as e-mobility or hybrid drive technology. Parallel to the expansion of the product range and the development of new components, the realisation of cost-effective large-scale solutions is also on our agenda here. The construction of another production hall with an office wing at our headquarters in Bad Homburg, which is now underway, and the swift expansion of our plant in Bosnia-Herzegovina should also be seen in this context, as should our bundle of sales measures for improved lead generation and market development.

Let’s stay with the new construction in Bad Homburg and the expansion of production in the Balkans...

Maurer: ...with the new production hall in Bad Homburg we are expanding and modernising the production capacities in our areas of focus: brakes, clutches, couplings and shaft-hub-connections. This goes hand in hand with investments in new machines - for precision stamping, for example - and comprehensive process optimisation. The expansion of assembling and production capacities in Bosnia-Herzegovina, on the other hand, is an expression of the advancing internationalisation of our value creation. Turned and milled parts are increasingly being produced here and components for mass-produced freewheels assembled. The RINGSPANN Group now consists of 19 companies worldwide, five of which - in addition to the three plants in Germany - have their own production facilities.

On the topic of "mass production": Up to now, RINGSPANN has deliberately kept its distance in this regard. Will that change?

Maurer: Possibly. Whether it’s delivery reliability, delivery times, response times, product quality or service - we have gained enormously in efficiency and flexibility through the process optimisation and reorganisation of the recent past. In addition, for two years now we have been producing cage freewheels in the millions on a production line set up specifically for this purpose. We now also consider it conceivable to enter market segments that are new to us, such as large-scale automotive production. Especially since the current technological change is presenting new opportunities for suppliers.

But wouldn’t you then come into contact with new, powerful competitors?

Maurer: We are used to competition and fast and flexible suppliers like RINGSPANN always have an advantage in markets in a state of flux. Especially if they bring their own development and engineering know-how from almost all key technological sectors. We will not rush into anything, but we are currently examining various options in diverse market segments. In this context, we have now also established a new role of business development. And crucially, we are currently in the process of making RINGSPANN’s sales machinery even more intelligent and powerful.

You already mentioned measures to improve lead generation and market cultivation....

Maurer: ...right, the focus for us here is directing our resources with even more precision than before at customer structures with high growth potential and considerably intensifying our new customer business. To this end, we are professionalising lead generation on several levels, optimising customer care and service and strengthening our real and media market presence. The high level of digitalisation of our business processes that we have achieved provides us with numerous opportunities to do so.

How do you see RINGSPANN positioned in terms of digitalisation?

Maurer: Very well! We have already achieved a lot in this area and are currently implementing further measures. All companies within the Group now use the wide-reaching process-analytical and communicational possibilities of SAP as an ERP back office. A new CRM system is now being added as a standardised front office, which will substantially improve the quality and efficiency of customer contact and customer care. 3D CAD has long been standard in design and our EDI - electronic data interchange with customers - is on the rise. All employees in production have e-mail accounts at the machines, electronic notice boards provide the latest information about current events on our intranet and projects for the further digitalisation of work activities and processes are being implemented in almost all operational areas. In the context of "intelligent market processing", we will also use all relevant online channels even more intensively - this refers, for example, to our website with the online shop, the publication of practical product videos or to the area of social media. Apart from that, the digitalisation of RINGSPANN’s products continues to make great strides. Our sensor-supported monitoring systems for backstops, the modern electronics of our e-brakes or the online calculation tools are pioneering.

Speaking of products: What innovations are RINGSPANN’s engineers currently working on?

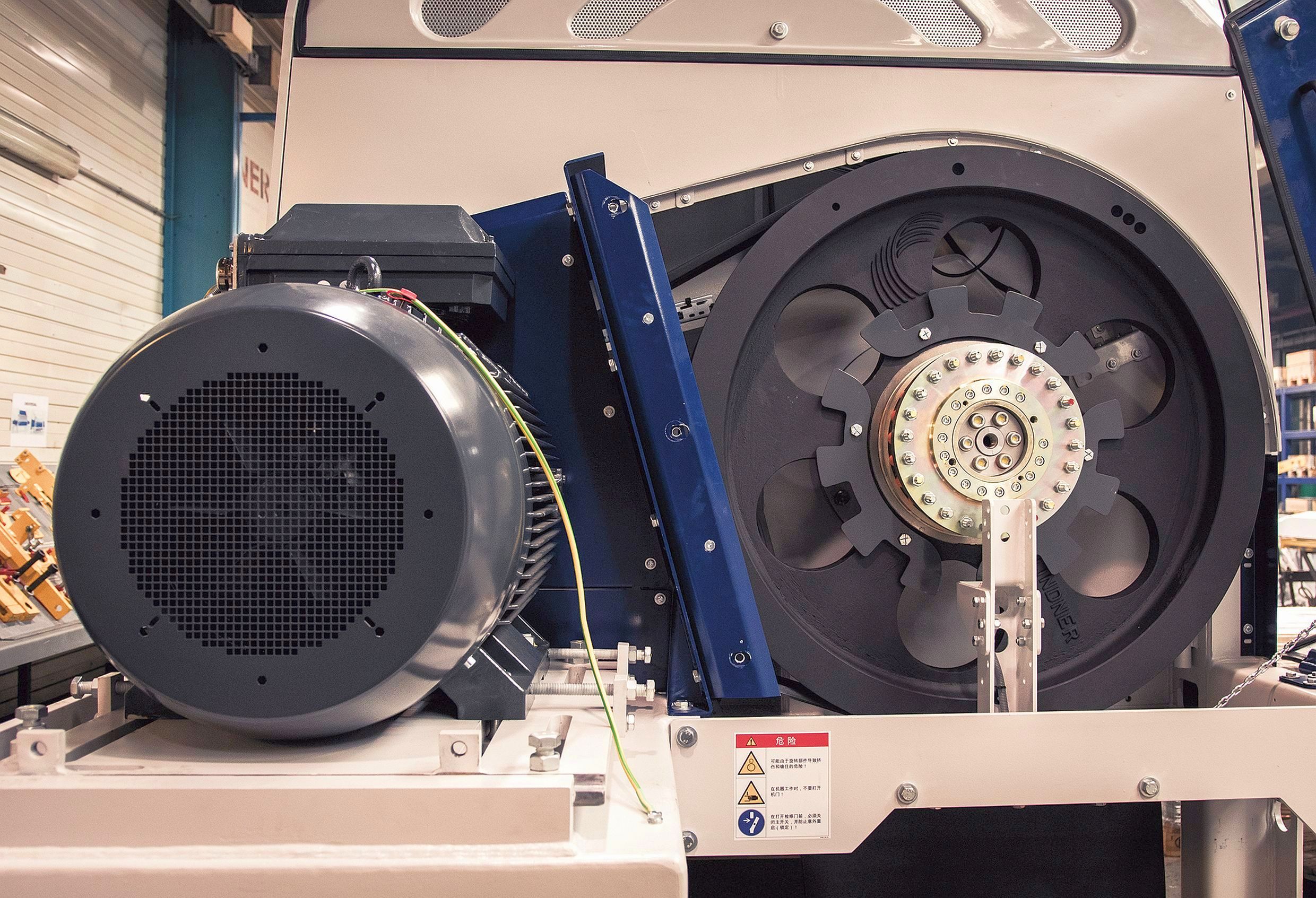

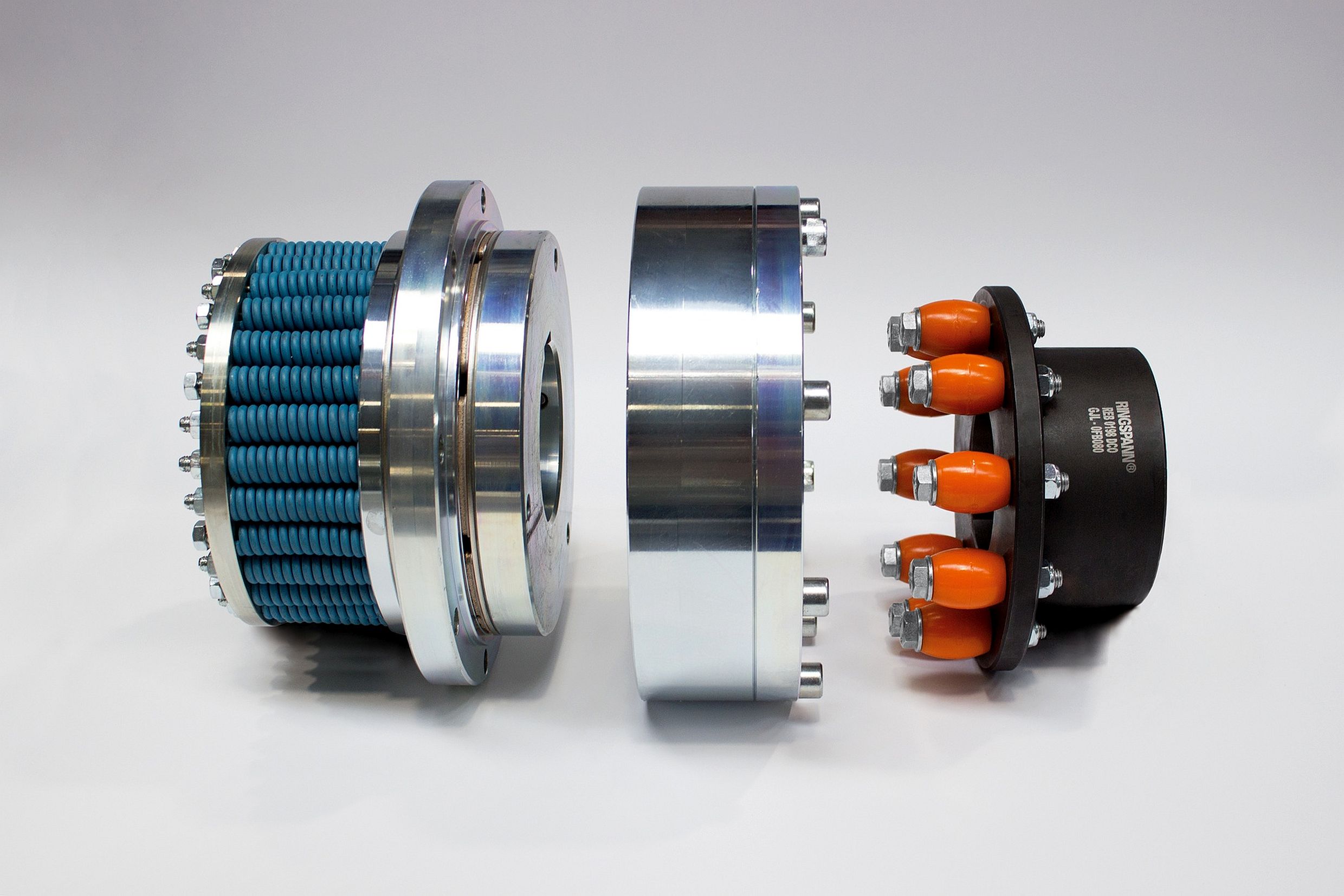

Maurer: In order to further develop our one-stop range for power transmission components, we have recently expanded the range of our shaft clutches in our online shop and added new functions and features to our electromagnetic disc brakes. In freewheels, the focus is currently on a new series for housing freewheels with hydrodynamic roller lift-off and the possibility of mechanically decoupling input and output, on optimising the operating condition monitoring for low speed backstops, and on designing new, particularly cost-effective freewheels for mobile drives. Our interdisciplinary development work in the field of smart solutions is likely to be of interest to many industries - primarily installation-ready combined solutions consisting of clutches, couplings and brakes. And the fact that we are now increasingly supplying complete system units consisting of friction torque limiters and belt pulleys is particularly popular with manufacturers of shredding and heavy-duty equipment.

And what is there to report from the precision clamping fixtures and push-pull cable sectors?

Maurer: Our precision clamping fixtures department has recently made a name for itself by presenting innovative clamping systems that are specially tailored to the requirements of the currently very popular hobbing process for the production of high-precision external and internal gears. An optimised taper collet flange mandrel solution for vertical balancing technology is also about to be launched. And the remote control specialists at RINGSPANN RCS are currently implementing numerous findings gained from their work with the new digital duplex test rig for push-pull cable systems. Something to look out for.

Mr Maurer, thank you for the interview.

Premium components for power transmission

As an international one-stop supplier for clutches, couplings and brakes, RINGSPANN offers a wide range of freewheels, brakes, shaft-hub-connections, shaft couplings and overload clutches. For gearing and balancing technology, the company offers high-precision standard and semi-standard clamping systems, and its subsidiary RINGSPANN RCS is one of the leading manufacturers of push-pull cables for bidirectional power transmission in mechanical operating systems.

In the area of freewheels, RINGSPANN is considered the world market leader and its portfolio covers more than 90 percent of all conceivable models and variants today. In the field of brakes, with almost 80 percent market coverage, the company is one of those manufacturers whose selection represents an almost complete technological cross-section of the world of industrial brakes. It’s a similar case for shaft-hub-connections. In the case of overload clutches, the portfolio currently represents about half of all possible products. The same applies to shaft couplings.

Through its main plant in Bad Homburg, seven other production sites worldwide and 19 international companies, the RINGSPANN Group currently supplies 6,000 customers in all branches of industry and sectors. The most important customers include manufacturers in gearbox construction, vehicle and aircraft construction, crane and construction machinery technology, railway and marine technology, energy and mining technology, e-mobility, food and packaging technology, machine tool construction and printing and paper technology.