2023-08-14

Slow runners in demand worldwide

FRHN backstops from RINGSPANN score points as a cost-effective quality solution

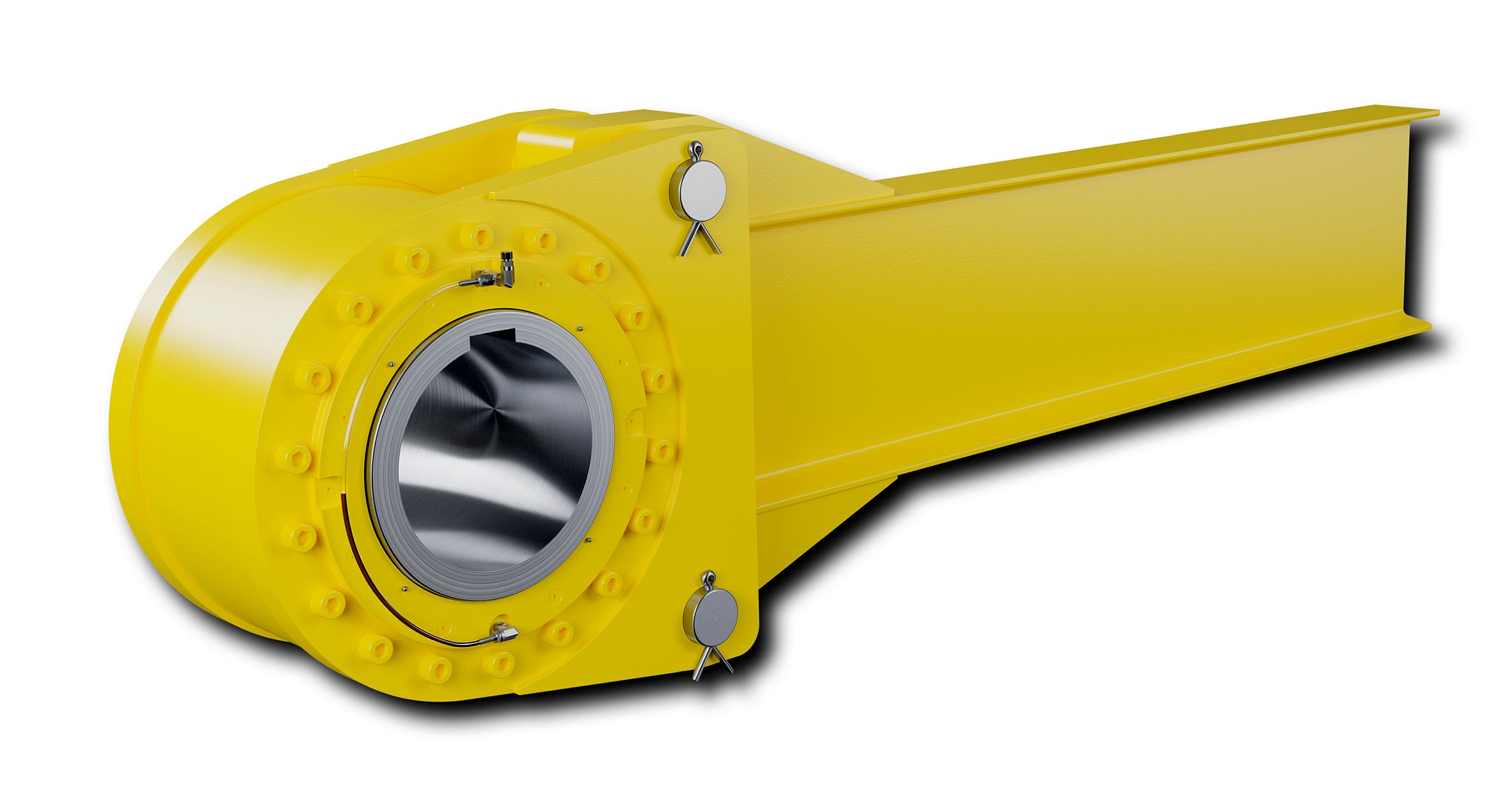

Backstops in machines and systems prevent uncontrolled and dangerous reverse rotation of drive shafts against the direction of operation. Low-speed backstops in the FRHN series from RINGSPANN are specially designed for use in inclined conveyor belt systems, bucket elevators or pumps. They have proven themselves worldwide as a standard solution that is as high in quality as it is cost-effective. Read here why these freewheels can be relied on even under adverse conditions.

Bad Homburg, August 2023. – Today, freewheels come in many different designs and dimensions. The current one-stop-shop from technology and market leader RINGSPANN alone offers drive technology designers and developers a freewheel selection that has at least one suitable series ready for almost every application. For example, the backstops in the FRHN series are tailor-made for use in conveyor and fluid technology. They are installed as mechanical-kinematic safety components in the drive trains of conveyor belt systems, bucket drives or pumps and prevent the unforeseen and sometimes extremely dangerous reversal of the shafts against the specified operating direction. FRHN backstops are specially designed for mounting on low-speed shafts in drive systems with low speeds. They are fixed on through shafts, or at shaft ends, and have their own lever arm for torque support.

“Features from the premium segment”

When developing these backstops, it was expedient for the freewheel specialists at RINGSPANN to optimally coordinate the two factors of cost-effectiveness and quality. In particular, internationally active manufacturers whose machines and systems have to survive in the Asian, Indian and South American low-cost markets are to be offered an attractive solution with the FRHN series. Marco Sommer, freewheel designer at RINGSPANN, therefore emphasizes: “These backstops are of high quality, impress with their robust construction and have quality features from the premium segment. These are ball-bearing and sealed clamping piece freewheels, which we provide oil-filled and ready for installation. They are also very resistant to dust and dirt.”

The FRHN series currently comprises a total of twelve standard backstops for maximum transmittable rated torques of up to 500,000 Nm and speeds from 110 to 620 rpm. Depending on the version, they have bores from 80 to 300 mm as standard and weigh between 50 and 1,600 kg. "This model selection covers a wide range of applications, such as those familiar from the design of drive systems for inclined conveyors, bulk material conveyors, trough chain conveyors, troughed belt conveyors or pump systems," explains Marco Sommer. The RINGSPANN backstops always form part of the safety equipment that is usually required by law. While during normal operation the freewheels rotate at idle speed, their clamping elements intervene immediately at the moment of an unintentional reverse rotation of the shafts. In this way, the FRHN backstops are used in the context of emergency-stop scenarios for accident prevention, operational safety and occupational safety. In the case of routine maintenance, dismantling or repair work as well, the backstops prevent the conveyor systems from running suddenly and uncontrollably backwards.

Always ready to listen

In addition to the range of catalogues, the RINGSPANN engineers are always ready to listen to the individual requirements of their customers. This means that it is also possible to implement special wishes for FRHN backstops – for example with regard to the holes, the design of the lever arm or other components. "The design adaptation and fine-tuning of our freewheels to the specific conditions of the users is always part of our range of services – regardless of the freewheel series," says Marco Sommer. ar

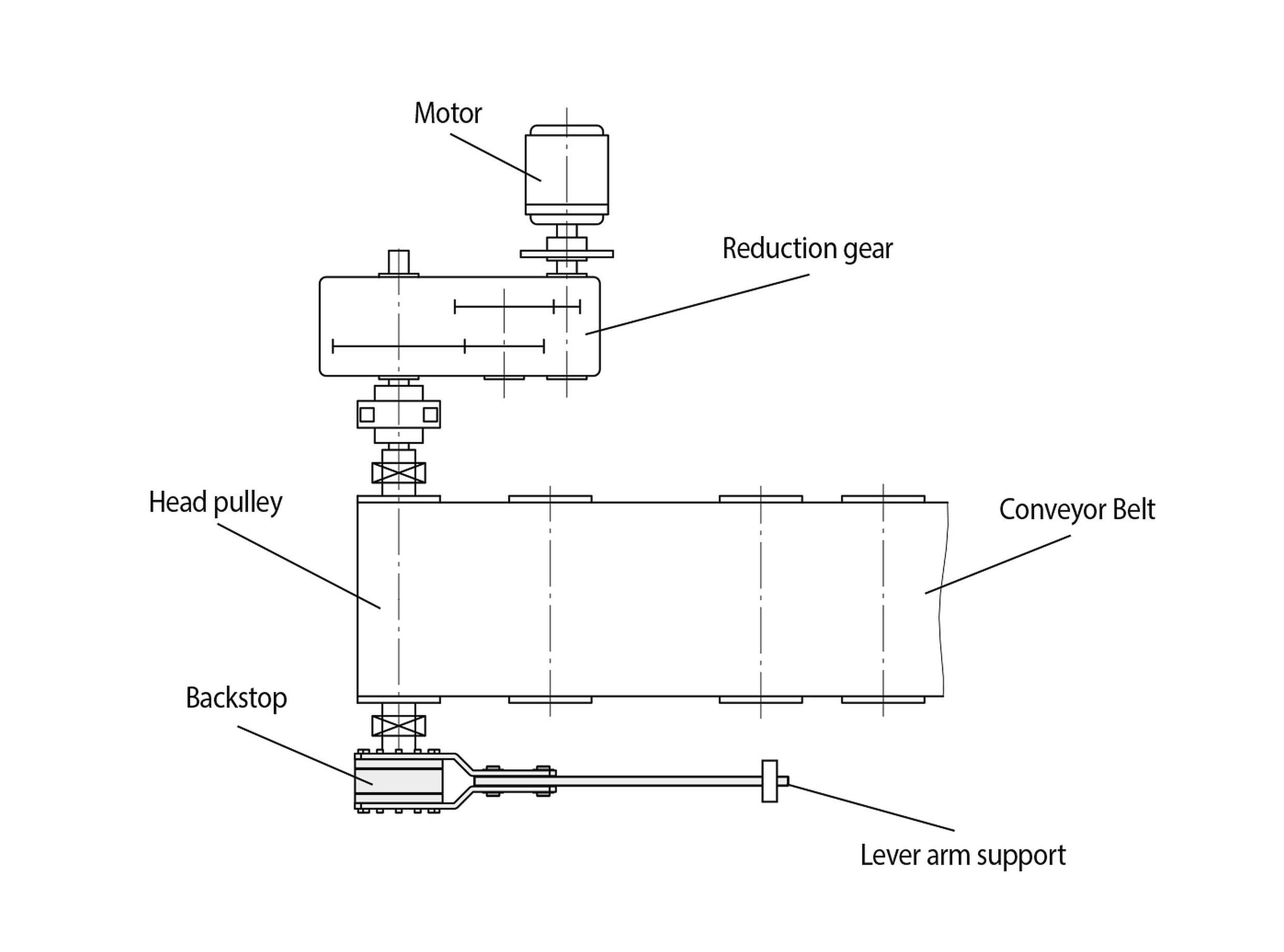

Example of an application: inclined conveyor belt

The graphic (Fig. 4) illustrates the use of a low-speed 1200 FRHN backstop on the head drum shaft of an inclined conveyor belt. The lever arm is attached to the freewheel via a bolt connection. The back torque is supported by the lever arm on the foundation. In the case of a load-free conveyor belt, loosening the bolt connection allows the drum shaft to be rotated in both directions for maintenance work. The lever arm is used for torque support and must not be clamped but must have at least 12.7 mm clearance in the axial and circumferential directions.