2017-05-22

Smooth and elegant, round and rust-free

RINGSPANN realises drive components according to the standards of hygienic design

The manufacturers of machines and plants for food processing and packaging adhere to the principles of hygienic design during construction. RINGSPANN realises a wide selection of tailor-made drive components conforming to these industry-specific requirements as a standard or custom solution. The company is particularly taking a leading role in the field of freewheels and overload clutches.

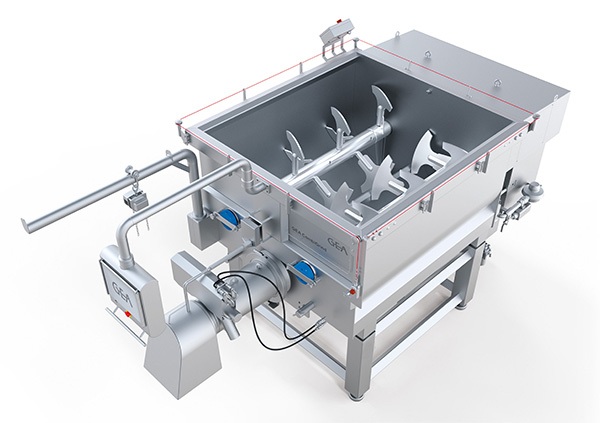

Bad Homburg, May 2017. – Machine and plant construction in the food and drinks industry follows its own rules. The design criteria of hygienic design play a key role for engineers and product developers among other things. This refers to ensuring a particularly cleaning-friendly design of plants and all components installed within. For suppliers, this means that they can only score in this market segment with components that meet the standards of hygienic design. Aspects of surface quality and part geometry become the main focus, just like the use of corrosion-resistant materials and food grade lubricants. The guidelines of the FDA (Food and Drug Administration) and the EHEDG (European Hygienic Engineering and Design Group) also must be taken into consideration. In the face of these industry-specific requirements, RINGSPANN’s power transmission divisions began to tailor defined sections of the product range to the unique features of the food industry. Today, the company supplies products such as freewheels, shaft-hub-connections, overload clutches and brakes for cutters, kneaders and mixers, as well as conveyor and packaging systems in the food and drink industry.

Free run in stainless steel

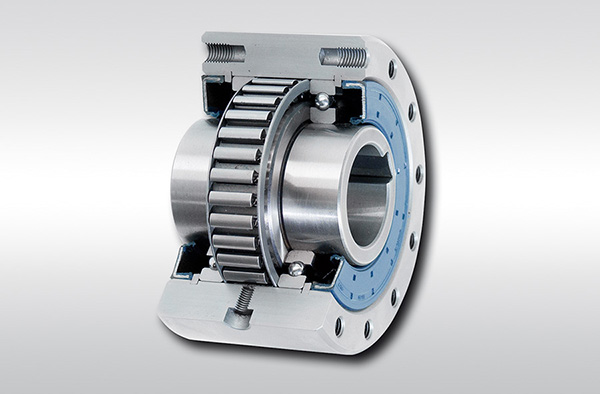

A drive technology highlight among RINGSPANNS’s hygienic design products are the FBS stainless steel freewheels, which were only freshly incorporated into the portfolio a few months ago. These installation-ready comprehensive freewheels for torques of up to 5,000 Nm are a wear-free alternative to actuated clutches. They can among other things serve as indexing freewheels in sausage machines, backstops in conveyor belts of filling plants and overrunning freewheels between the creep and main motors of meat cutters. RINGSPANN manufactures these freewheels from a rust-free special steel that was defined and specified in cooperation with renowned technology leaders in material engineering. They are therefore highly resistant against corrosion and acids – including nitric acid, which is found in many cleaning agents. The FBS series from RINGSPANN features nine sizes with bores of up to 75 mm and is equipped with food grade lubricants and seal rings.

RINGSPANN’s shaft-hub-connections also offer an array of possible applications in food mechanical engineering. Wherever the power transmission of drive shafts to pulleys, sprockets or brake discs must to be ensured, these connection elements can be integrated into the designs in the form of cone clamping elements or stainless steel shrink discs. For example, this can be the case in conveyor belts for bakery production or film packaging lines for fruit and vegetables.

Controlled disengaging

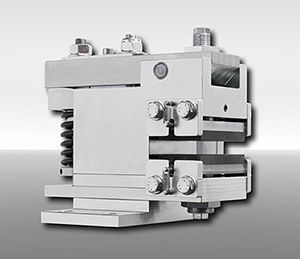

For reasons of operational safety, many plant manufacturers in the food and drinks industry place their trust in RINGSPANN overload clutches. Here, RIMOSTAT® friction torque limiters and the stainless-steel force limiters are particularly the focus of attention. While the friction torque limiters are installed in dough processing machines as overload protection between the chain drive and rolling pin, the stainless-steel force limiters serve as axial overload clutches in fully automated packaging processes. The RINGSPANN force limiters hereby offer a key advantage: Forces can be transmitted bi-directionally almost free of play and rigid up to a certain size. As soon as the defined disengagement torque is exceeded, the power flow is interrupted and the output element is no longer driven.

Another large product group of RINGSPANN that is strongly represented in the plants of the food industry are the industrial brakes. They are offered in all technically relevant types and operating principles. They are used, for example, as emergency-stop systems in the carousels of blow moulding machines to produce plastic bottles or in handling systems for food transport on pallets. A further area of application for RINGSPANN disc and drum brakes is the controlled pre-loading of film strips in automated fresh fruit packaging lines.

High level of development expertise

RINGSPANN is generally able to cover the design standards of hygienic design in many cases with components and systems from its broad standard or catalogue range. Often, the engineering division of the company also develops specially tailored customer or application-specific solutions for plant and machine manufacturers in food and packaging technology. RINGSPANN hereby not only profits from the close cooperation with the research organisation Forschungsvereinigung Antriebstechnik e.V. (FVA), but also from industry-specific material and engineering expertise that is gained thanks to the transfer of knowledge between the production plants in Germany, South Africa and Asia.

Drive components in hygienic design

In the production surroundings of the food and drinks industry where hygiene is critical, the prevention of microbial and particulate contamination ranks among the most important quality requirements. The selection of materials and the geometric design of equipment must therefore follow the standards of hygienic design, which primarily refers to the cleaning-friendly design of elements, components and plants. For RINGSPANN’s engineers this specifically means that when developing the power transmission components, a strong emphasis must be placed on realising minimal surface roughness values of Ra ≤ 0.8 µm, preventing hidden edges and dead ends, as well as the use of corrosion-resistant stainless steel materials and food grade lubricants and seals. Numerous components of RINGSPANN products are also geared towards the guidelines of the FDA (Food and Drug Administration) and the EHEDG (European Hygienic Engineering and Design Group).