2020-03-17

The functional link in hybrid drives

RINGSPANN freewheels regulate the dynamic interaction between the motors

When manufacturers of mobile cranes, construction machinery or heavy transporters develop their engines, RINGSPANN’s freewheels are often involved. These special vehicles are often driven by powerful hybrid systems consisting of diesel and electric motors. The overrunning clutches from the FKh series , for example, are responsible for the division of labour between the two. The reason for this is that without complex control technology, this hydrodynamic clutch solution allows both high differences in speed between the engines to be achieved and different engines of the same drive train to be alternately engaged and disengaged.

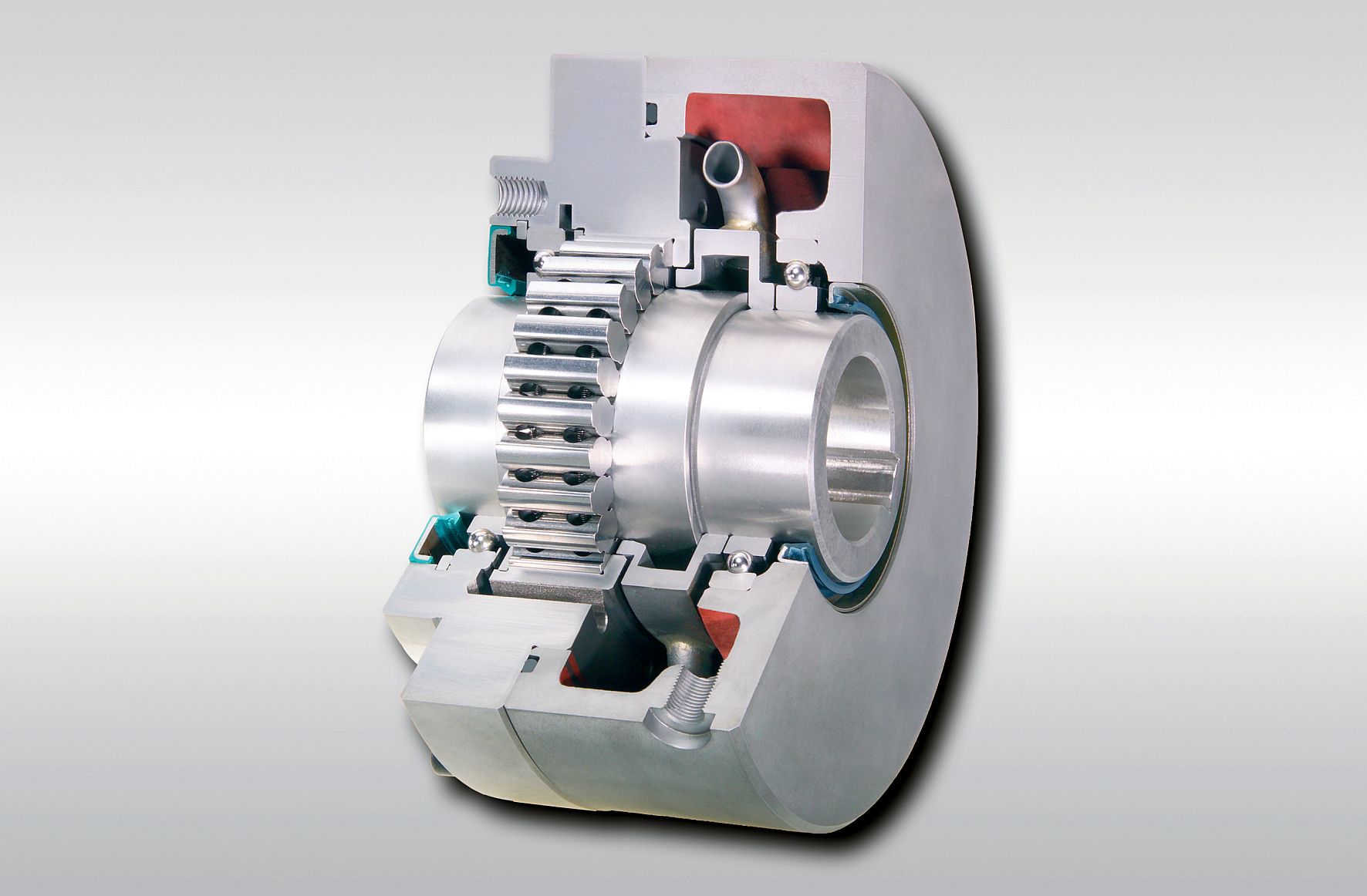

Bad Homburg, March 2020. – Hybrid drive solutions are becoming increasingly popular in the off-highway and heavy-duty sectors of international vehicle construction. Today they are being used in mobile cranes and heavy-duty transporters as well as in many earthmoving, road construction and construction site vehicles. Typically, these hybrid engines combine modern diesel engines with powerful (asynchronous) electric motors so that the wheels of the mobile machines can be driven either by one of the units or by both in a duet. Now, however, the user must be able to rely on this work-sharing interaction between the combustion engine and the e-drive functioning reliably and efficiently over a long period of time. Many designers of hybrid drives therefore use overrunning clutches from RINGSPANN. The freewheels of the FKh series have particularly proven themselves as dynamic mediators between the rotating forces of the systems. “These ready-to-install complete freewheels for front-side bolted assembly often prove to be the ideal solution for the safe and simple management of high speeds in hybrid engines with a spatially optimised design. This is primarily due to their hydrodynamic sprag lift-off, which is ideally suited for changing between freewheeling and driving operation in multi-motor drives where the speeds are the same in both operating modes”, says Thomas Heubach, head of the freewheels division at RINGSPANN.

Coupling and uncoupling without an external impulse

The overrunning clutches of the FKh series from RINGSPANN are low-maintenance components with ball bearings that can be used to engage and disengage the various engines of hybrid drive systems. This type of freewheel can be used as a compact clutch between electric motors and combustion engines in joint (or parallel) drive trains. The clutch is engaged with torque transmission in driving mode of the freewheel, while disengagement with torque interruption is carried out in freewheeling operation. Both of these operations can be carried out without any addition control or regulating technology, because the functionality of an FKh overrunning clutch is based solely on mechanical and hydrodynamic principles. The freewheels are always installed between the two drive sources of the hybrid system in such a way that the drive in driving mode is carried out via the inner ring, while the outer freewheel ring overruns in freewheeling operation.

Oil flow instead of centrifugal force

The hydrodynamic principle is the great strength of this freewheel series from RINGSPANN and makes it so attractive for use in fast-rotating multi-motor engines. In contrast to freewheels where the sprags lift off solely due to the centrifugal forces acting during rotation, the sprag lift-off in hydrodynamic overrunning clutches is achieved by an oil flow. “For this reason, in an FKh freewheel, the speed in driving operation can be as high as the freewheeling speed in freewheeling operation”, stresses division manager Thomas Heubach, and explains what this means in practice: “This results in an almost unlimited service life of the sprags, which float on an oil film in overrunning operation and are thus separated from the inner raceway. The maintenance expenditure is minimal and is limited to an occasional oil change. These systems are therefore also extremely reliable and far superior to others in which no mechanical centrifugal lift-off can be used.”

RINGSPANN supplies the overrunning clutches of the FKh series in six standard sizes, filled with oil and ready for installation, for nominal torques up to 14,000 Nm and with bores ranging from 35 mm to 95 mm. Sizes FKh 94 ATR and FKh 106 ATR are currently in healthy demand among manufacturers of hybrid engines for mobile cranes, construction machinery and heavy transporters. Division manager Thomas Heubach is also of the opinion “that hybrid drive technology still possesses great development potential in automotive engineering and is a growing future market for hydrodynamic overrunning clutches. Particularly because it allows solutions to be realised that do not require any electronics at all and is therefore very easy to maintain.”

The entire freewheels range can be found in the company’s online shop.

Hybrid drives in shipbuilding

Highly illustrative examples for the use of overrunning clutches in hybrid drive systems can also be found in shipbuilding. In large cargo and passenger ships, the use of overrunning clutches enables switching from diesel propulsion at sea to electric motor operation in port – quiet, slow, and environmentally friendly. While the diesel engine does the work, the electric drive can serve as a generator – in this case the freewheel couples the drive train together. But if the electric motor takes over and the diesel engine takes a break, the freewheel disengages the drive train.

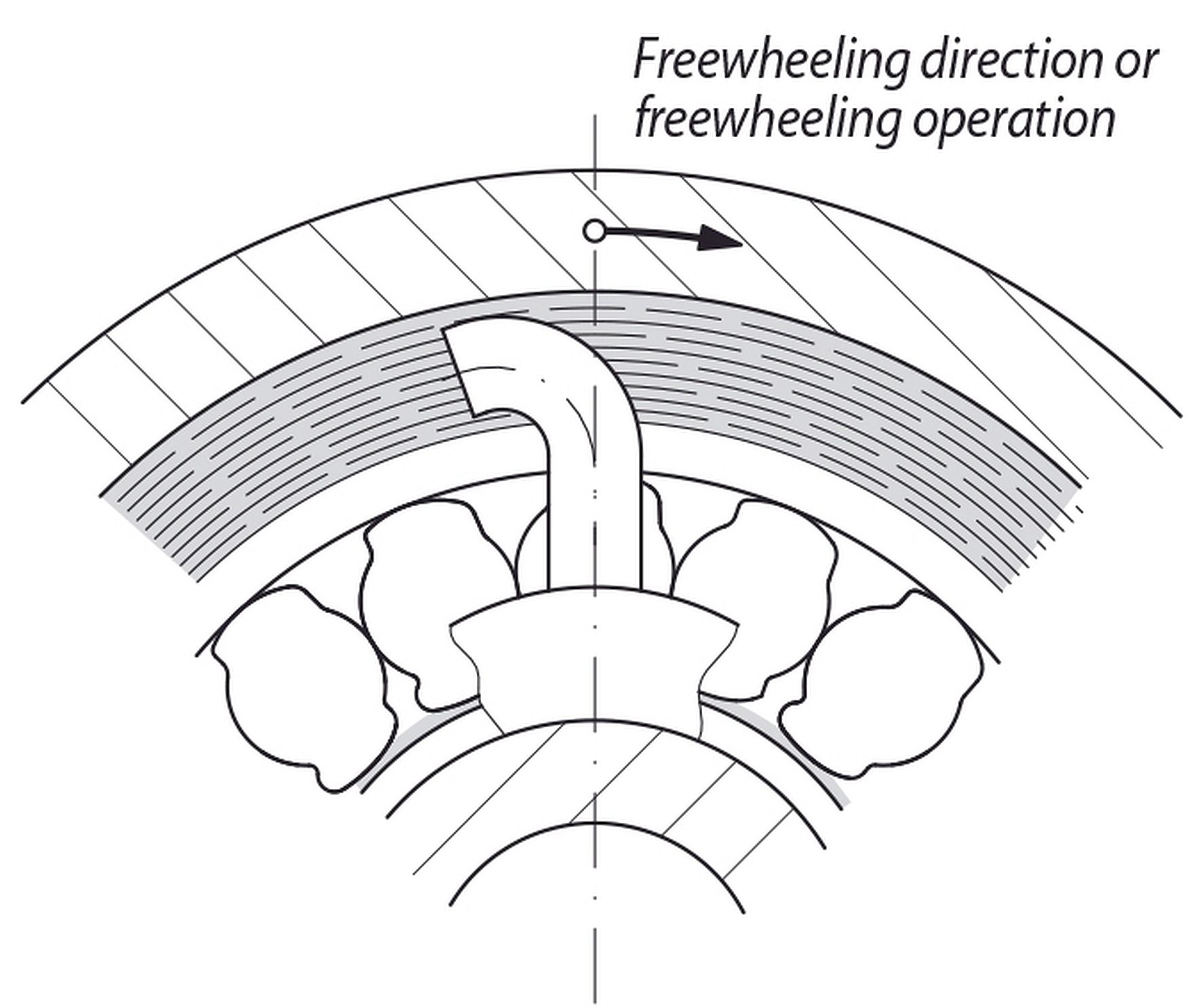

How the hydrodynamic sprag lift-off works

A hydrodynamic freewheel has an oil chamber with a pump, whose pitot tubes are connected with the inner ring of the freewheel. When the outer ring is rotating, a 360° oil flow forms in the oil chamber, into which the pitot tubes are immersed. As soon as the outer ring overruns the inner ring, the tubes pump the oil under pressure into the ring chamber. From here, it seeps out through the ring gap at high speed into the intermediate areas of the sprags. Depending on the relative speed between the outer and inner ring, the oil flow does not flow axially into the intermediate areas of the sprags, but at an angle. This creates a reaction force on the sprags. This reaction force overcomes the contact force of the sprag springs, and the sprags lift off from the inner ring. This kinematic is supported by the hydrodynamic lubrication wedge. If the relative speed between the outer and inner rings reduces, the lifting force also reduces. Before achieving synchronous running, the sprags are brought safely to rest on the inner ring and are ready to lock. This guarantees immediate torque transfer once the synchronous speed has been reached. The hydrodynamic sprag lift-off enables a virtually wear-free freewheeling operation.